by

Joe Russo

Products & Apparel

April 30, 2022

Everyone has owned a screen printed tee at one point in their life. Screen printing is one of the most common and cost effective ways to print shirts in bulk. While screen printing is one of the most common methods for printing shirts, it isn’t the only way. What is screen printing and how does it compare to other common printing methods?

Common Printing Methods

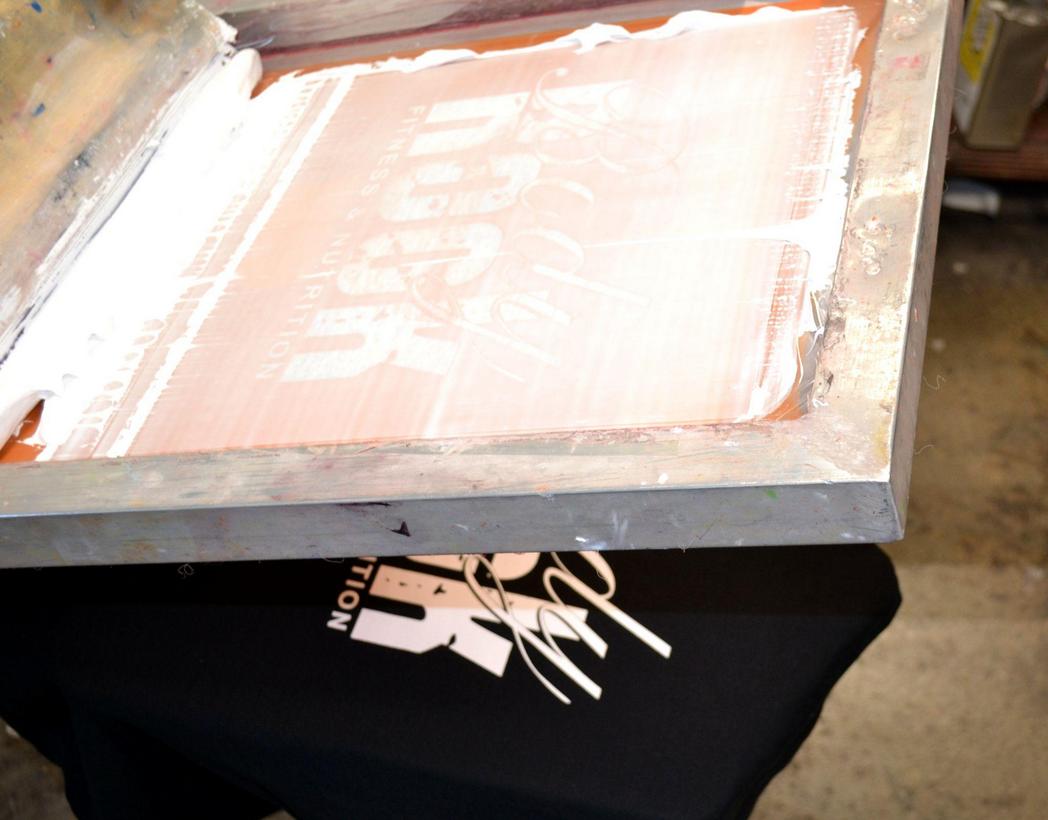

Screen printing is the process of running ink over a screen to create a desired design or effect on a product. Screen printing can be used on nearly any blend of material, making it a widely effective method. There are multiple types of inks you can use for screen printing, but Plastisol is by far the most common. Plastisol tends to print well on dark garments, which is a common issue for printing methods like sublimation. The screens used in screen printing can be made from a variety of materials, like silk or polyester.

The process of screen printing begins with a design cut from the screen. The cut part should be where you want the ink to embed on the shirt. The ink is then loaded onto the screen and pushed across its length with a squeegee or brush. Once the ink has been pressed into the shirt, it is left to dry. A heat gun can speed up the drying process. While the ink can be made thinner or thicker by changing the plasticizer ratio or adding more coats, respectively. Once the screen is set up, it’s easy to continue printing that design across shirts, whether it’s 100 or 1,000.

Sublimation is the process of digitally printing an image onto a transfer sheet with dye. This sheet is then pressed into a light color shirt that’s made of 70% or higher polyester. When heated, this dye is brought from a solid state to a gaseous state, dying the fibers of the shirt in the process. Because you’re dying the fibers of the shirt directly, you aren’t getting a plastic feeling left behind. Because of the time it takes to create these transfer sheets, sublimation works best in smaller batches.

The Downsides

There are a few downsides to screen printing. Unfortunately, because the ink has a plastic content, it tends to leave a plastic feel on the final print. This is one of the main ways to distinguish between screen printing and sublimation. Screen printing is also semi-limited in the amount of colors you can print and the complexity of the design. The difficulty to print a lot of colors on a screen printed shirt also can cause delays and mistakes when printing. Most screen printers will limit you to a maximum amount of colors, usually 6.

Sublimation also has its downsides. While it does not leave the same plastic feel on the shirt, this method is impractical for printing more than a few shirts at a time. Sublimation can only be done on light or white garments that are around 70% or higher polyester.

There are downsides to screen printing (as there are with any printing method), but screen printed apparel has stood the test of time and continues to be one of the primary printing methods used today.